The International Energy Agency (IEA) has sounded the alarm over rising vulnerabilities in global critical mineral supply chains, warning that a full-blown trade war between China and the U.S. could paralyze the entire global technology sector almost overnight, given the sector’s heavy dependence on a handful of critical minerals.

In its 2025 Global Critical Minerals Outlook, the agency revealed that markets for essential minerals—including copper, lithium, nickel, cobalt, graphite, and other rare earth elements—are becoming increasingly concentrated. China holds a leading refining position in 19 of the 20 strategic minerals analyzed, accounting for an average 70% share of global refining capacity.

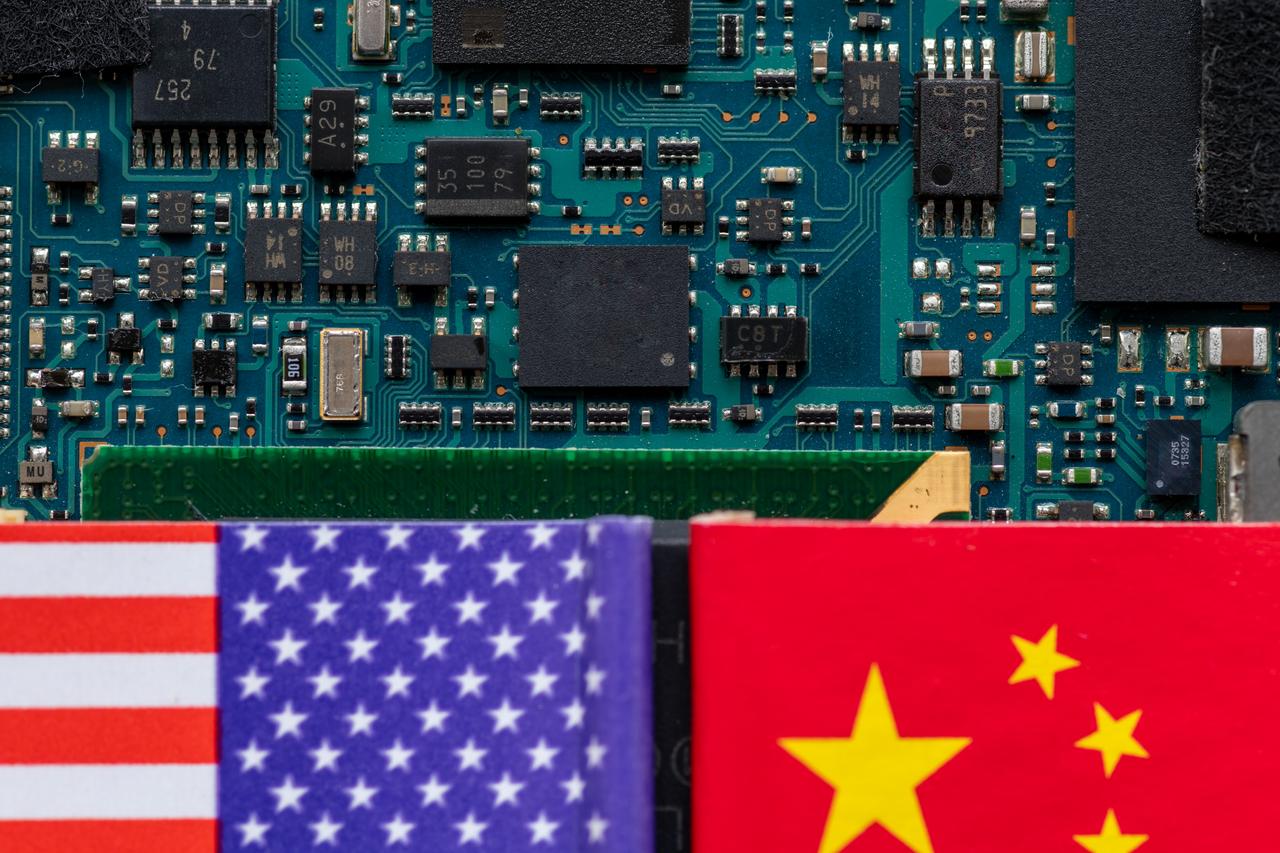

These minerals form the backbone of virtually all modern technology—from smartphones and electric vehicle batteries to aerospace components, semiconductors, robotics, and artificial intelligence hardware. Without a secure and diversified supply of these inputs, the global production of high-tech goods risks grinding to a halt.

"If you do not refine the mineral, it is of no use. China has become the leading refiner in 19 of the 20 critical minerals we studied. They have invested in this for two decades," IEA Executive Director Fatih Birol told Turkish news outlet Hurriyet, speaking on the findings of the report.

Birol emphasized that control over refining—not just mining—is what defines strategic dominance. He noted, for instance, that while Australia extracts 35% of the world’s lithium, it processes only 2%, exporting the rest to China. Similarly, just 5% of global nickel and cobalt output originates from China, yet the country commands near-total control over their refining.

According to the IEA, the combined market share of the top three producers in these minerals increased from 82% in 2020 to 86% in 2024.

"In a world of rising geopolitical tensions, critical minerals have moved to the forefront of global energy and economic security. A single export restriction on one of these materials could paralyze entire industries," Birol said, referring to recent trade escalations.

Following U.S. President Donald Trump's announcement of reciprocal tariffs—particularly a 34% levy on Chinese imports—China introduced countermeasures, including the suspension of critical mineral exports targeting high-tech sectors.

While tensions initially escalated rapidly, recent diplomatic overtures have signaled a tentative thaw. The Geneva meetings, held earlier this month, resulted in a provisional framework aimed at preventing further supply chain disruptions, with both sides agreeing to reassess export controls and tariff measures in the coming weeks. However, the underlying risks remain, as no binding resolution has yet been reached.

The IEA report warns that 55% of the 20 strategic minerals examined are now subject to some form of export control, which increasingly includes not just raw and refined materials but also processing technologies.

Moreover, 15 of these 20 minerals have exhibited more price volatility than crude oil. Disruptions such as pandemics, natural disasters, and trade restrictions amplify the risks, even in markets that may appear well supplied.

Despite easing prices since the 2021–2022 peaks, the report flags long-term concerns. One of the most significant is the potential for a 30% copper supply shortfall by 2035, should current demand trends—driven by power grid expansions—continue without sufficient new mining projects.

"Without these critical minerals, producing robots, aircraft, drones, or AI-powered technologies is impossible. The world is fully dependent on China for these materials. Even a six-month export restriction could disrupt an entire sector," Birol added.

The report also outlines how investments in the sector are failing to keep pace with demand. Capital expenditures in critical minerals rose only 5% in 2023, down from 14% in 2022. Exploration activity, which had been growing steadily since 2020, also plateaued in 2024.

The IEA additionally reviews supply chains for emerging battery technologies such as lithium iron phosphate (LFP) and sodium-ion batteries. While these technologies are touted as alternatives, their input materials—such as manganese sulfate and phosphoric acid—are also heavily reliant on Chinese production.

"We can’t resolve this trajectory through trade or protectionism alone. Nations must invest in refining capacity and work together to identify where each can best contribute," Birol said.