A team of researchers in Türkiye has developed a natural sunscreen that combines melanin extracted from cuttlefish ink sacs with antioxidant pigments derived from laboratory-grown microalgae. The product, which has completed prototype and registration stages, is expected to enter mass production following further clinical evaluations.

The project was carried out jointly by Associate Professor Murat Telli of Bolu Abant Izzet Baysal University and Associate Professor Gizem Kaleli of Izmir Demokrasi University.

The researchers began their work after the U.S. Food and Drug Administration (FDA) issued reports noting that many chemical-based sunscreen ingredients previously considered safe might accumulate in the body and potentially lead to harmful effects.

Telli explained that this concern encouraged the team to look for an ingredient compatible with human skin. Melanin pigment was identified in the ink sacs of cuttlefish, which are widely consumed and processed in Türkiye, making the ink sac an abundant byproduct. Melanin is naturally produced in the human body and plays a role in the skin’s response to sunlight.

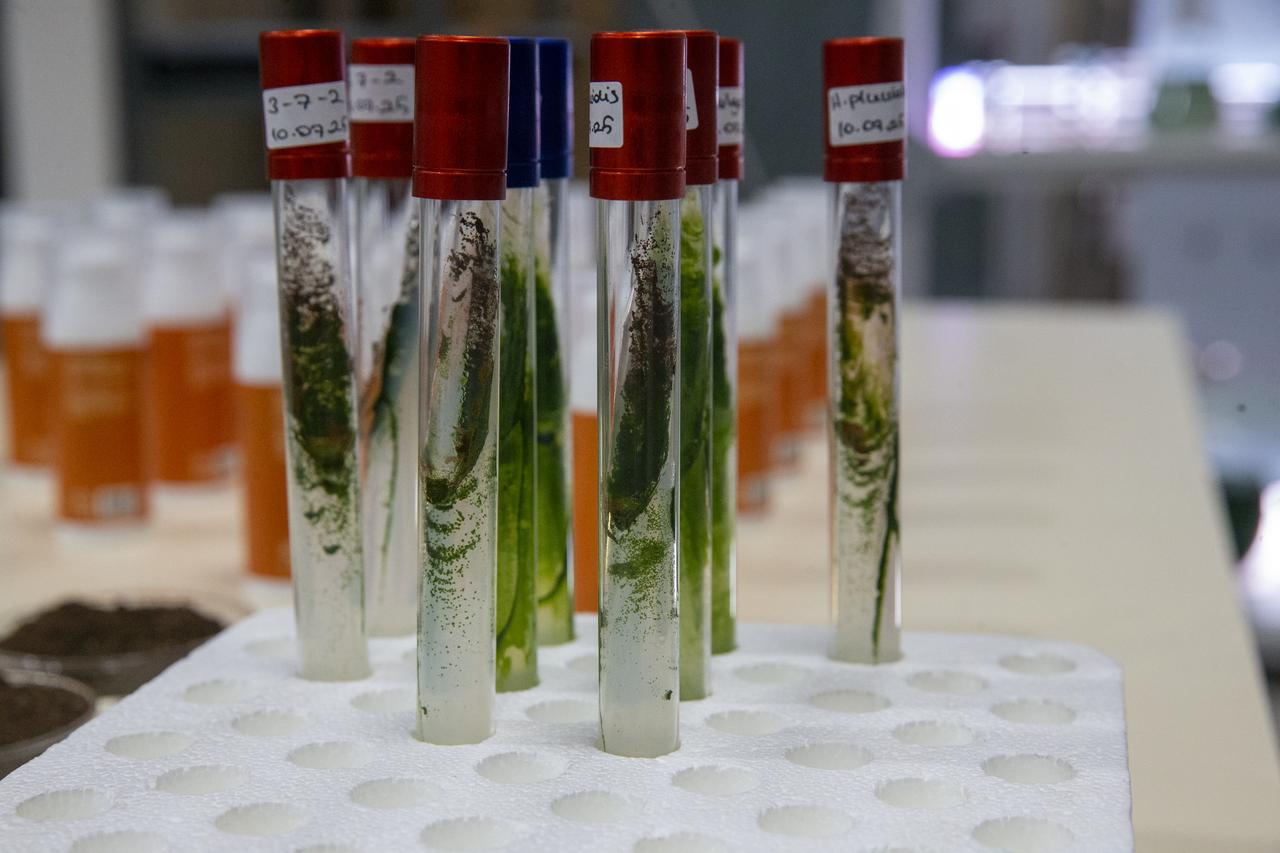

The team combined the extracted melanin with pigments obtained from microalgae, particularly a high-antioxidant compound known as astaxanthin. The two components were processed into composite nanoparticles and then incorporated into a sunscreen formulation.

According to Telli, the product’s sun protection factor (SPF) can reach levels comparable to widely used commercial sunscreens, ranging up to SPF 50 or even higher, depending on the final formulation. He noted that previous attempts to develop melanin-based sunscreens had faced difficulties achieving adequate SPF protection, while their formulation was able to overcome this challenge.

The melanin in the product absorbs sunlight to help prevent skin damage, while the astaxanthin is gradually absorbed to support skin repair. This dual effect aims to protect the skin during exposure and assist recovery afterwards.

The researchers emphasized that all raw materials were sourced domestically and that the production process aligns with carbon-negative principles due to the nature of microalgae cultivation. The product, therefore, does not contribute to carbon emission impact, and the cuttlefish ink sacs used in the process are typically considered waste materials.

Clinical and microbiological testing has been completed in line with requirements set by the Ministry of Health in Türkiye, and human-based evaluations are ongoing at an accredited laboratory abroad.

The team has signed with a manufacturing partner and aims to launch the sunscreen both nationally and internationally once the final certification steps are completed.

Discussions with investors in Europe and Asia are currently underway.